NFB-H Series HIGH EFFICIENCY CONDENSING HEATING BOILER

Navien Keeps Raising The Bar Higher And Higher In Fire Tube Boiler Innovations

Navien Reinvented Fire Tube Technology From The Ground Up And Continues To Advance Boiler Technology To A Higher Level With The New NFB-H Boiler Series.

- Patented stainless steel fire tube heat exchanger—reduces high stress point welds

- Advanced user interface with intuitive text display and Quick Dial Wheel for easy navigation

- Smart controls with Setup Wizard to simplify boiler start up

- Built-in 3 zone pumps or 3 zone valves powered connections

- Optional NaviLink Wi-Fi remote control

- Common venting up to 8 boilers

- Cascading up to 16 boilers

- Up to 15:1 turndown ratio

- AFUE 95.0%—Energy Star certified

- Compact, light weight, wall hung design saves space over traditional floor standing boilers

COMPARE these advantages and see why

NFB-H boilers are the right fit for small and

large homes

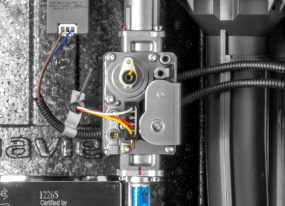

Low gas pressure operation

Negative pressure regulating gas valve ensures maximum performance all the way down to 3.5″ of water column on natural gas and 8″ of water column on propane gas.

Space saving and light weight design

The sleek wall-hung design uses much less space and is substantially lighter than traditional floor standing boilers, making installations a lot easier.

Dual Venturi and field gas convertibility

Dual Venturi system creates better combustion control and turndown ratio. Field gas convertibility is easy with orifice conversion kits for NG high altitude (5,400–10,100 ft.) and LP (up to 10,100 ft.) included with NFB-H Series boilers.

Uses existing 1/2" gas piping

Save time and cost in retrofit application by reusing existing ½” gas lines for up to 24′ in length. Subject to local code.

Low noise levels

Installations in or near media rooms, recreation rooms or any living areas of the house are possible with the quiet running NFB-H boilers.

Up to 15:1 turndown ratio

The sophisticated gas flow control system provides a high turndown ratio which reduces energy waste and excessive boiler cycling.

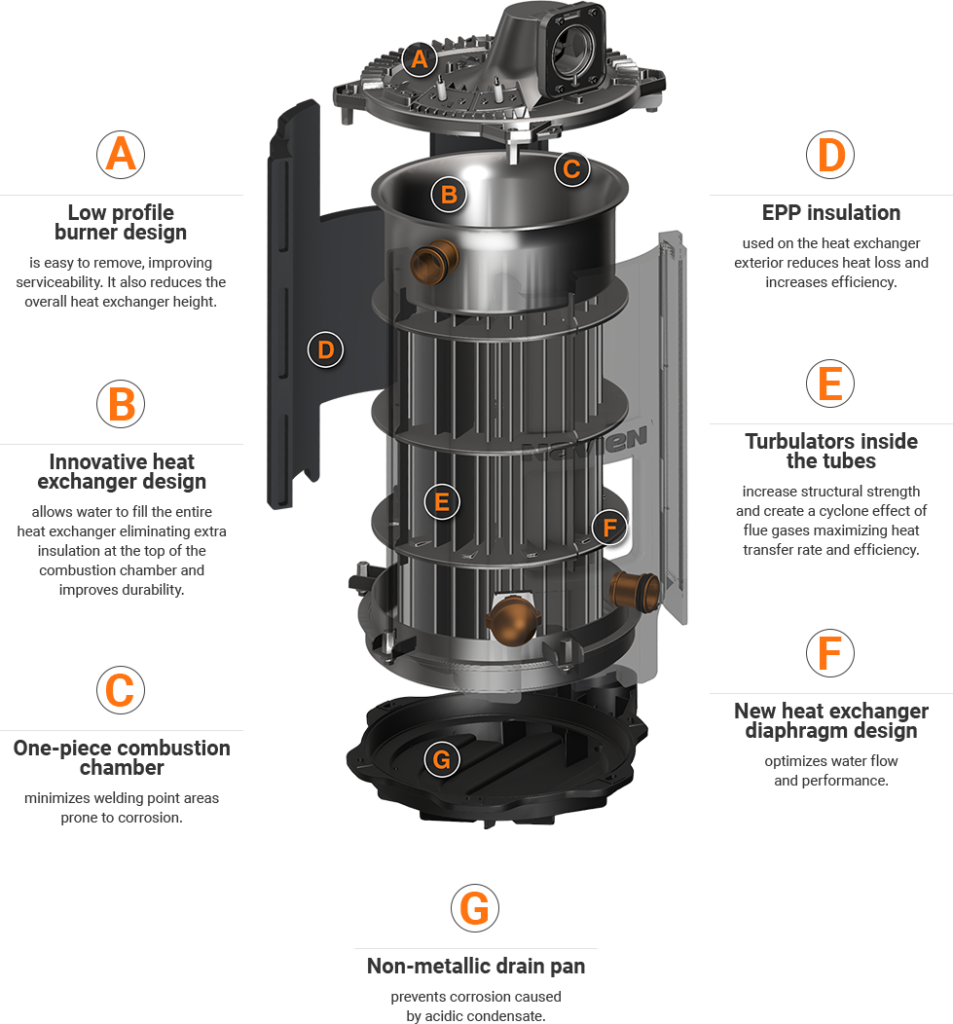

Patented Stainless Steel Fire Tube Heat Exchanger With

Laser Weld Technology

Navien’s advanced patented stainless steel heat exchanger is designed and manufactured in-house using robotic laser welding to deliver higher product quality. The ASME‑Certified, “H” Stamped, design also reduces high stress point weld failures common on other boilers.

Common Venting Up To 8 Units And Cascading Up To 16 Units

With Navien’s cascading technology, when a unit gets up to capacity determined by the supply and return temperatures, the next unit will start to help meet the hydronic space heating requirements. This boiler sequence will continue until all units are generating the needed hydronic space heat up to the maximum cascaded capacity.

The Navien cascading system also balances out the workload of each unit for longer life. The NFB-H is dual certified for direct and non-direct venting applications.